The Lithium Battery Paradox: Energy vs. Environment

The American scientist, inventor, and founding father Benjamin Franklin first used the term “battery” in 1749 when conducting experiments with electricity using linked capacitors. However, Italian physicist Alessandro Volta invented the first true working battery in 1800. He stacked discs of copper (Cu) and zinc (Zn) separated by cloth soaked in salt water.

Fast forward 270 years, as global efforts continue to drive innovation towards alternative energy solutions and lithium-ion batteries, also known as Li-ion batteries (LIBs), have rapidly emerged as a cornerstone energy technology. Innovations in LIBs energy density continue to provide the energy, automotive, and tech industries with smaller batteries capable of greater energy capacities.

Additionally, their long lifetimes, low toxicities, and lightweight configurations position LIBs as one of the most dominant battery technologies of the future. Yet even though LIBs can propel green energy solutions into ubiquity, paradoxically, one of the greatest hindrances to LIB’s is the burden sourcing raw materials places on the environment.

Procurement of raw materials such as lithium, cobalt, and graphite have a variety of environmental and safety considerations that need to be addressed to ensure ethical development practices. So, let’s talk about the issues surrounding raw material procurement, emphasizing how to solve them.

What is a lithium-ion battery made of?

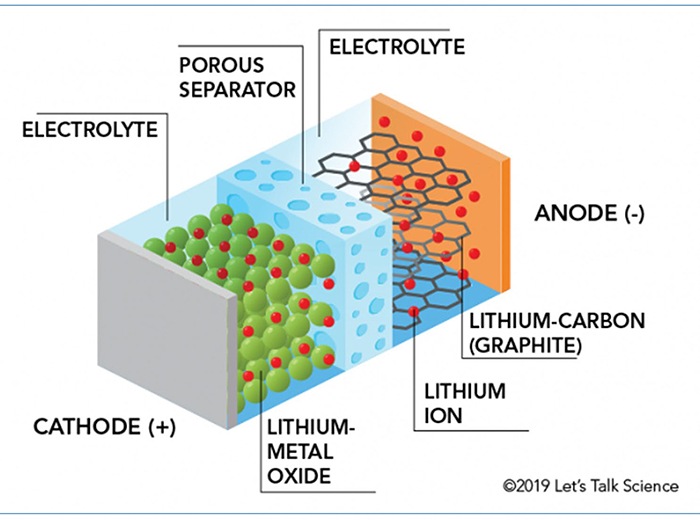

LIBs consist of a separator, electrolyte, negative electrode – commonly graphite, and a positive electrode, typically layered lithium transition metal oxides, i.e., cobalt, nickel, and manganese.

(Figure 1.) The separator, acting as an insulator, is saturated with an electrolyte, i.e., lithium hexafluorophosphate, which is dissolved in organic carbonate solvents.

General Anatomy of a Lithium-Ion Battery.

The only way to extract these materials is by mining. Mining and high purity metal refinement will continue to increase the complexity of processing techniques in the future. Safety considerations and operational benefits are the primary mechanisms driving the evolution of mining’s technological innovations.

Primary safety concerns

Raw material extraction workers face include exposure to high levels of metal particulates found in dust during extraction and high-risk operational tasks.

Contaminated Dust Exposure

Dust particles containing graphite pose a severe concern in mining cities like Mashan, China. Mining operations and processing plants are blanketed with copious amounts of graphite-laden dust, posing a serious health risk to workers.1

Mining Hazards

In addition to exposure via inhalation of contaminated dust particles, mining raw materials for LIBs pose other operational hazards. Common hazards include fire and explosions, working from elevated positions and confined spaces, chemical exposures, and noise-related injuries.

Industry 4.0: The Age of Robotics

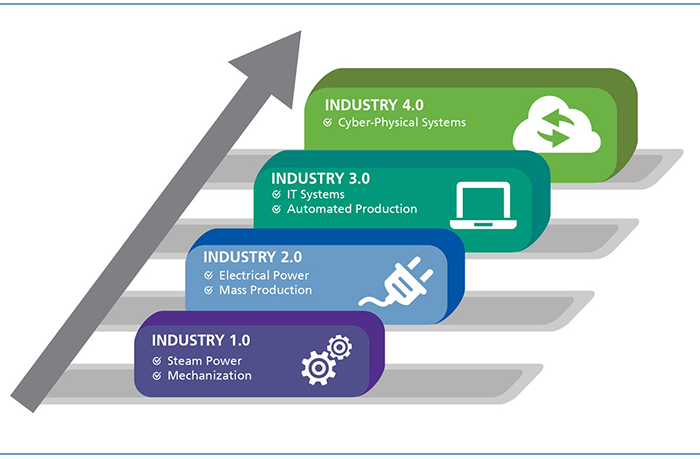

Technological advancements are bringing about transformation in the mineral extraction industry, ushering in a paradigm dubbed “Industry 4.0”, which is broadly characterized by a more-seamless integration of devices and technology with physical and mechanical systems.

These safety concerns have pushed the mining industry to replace laborers with remote-controlled and autonomous robotic equipment. A key benefit of these technologies is the ability to expand the exploration of flooded mines and deep-sea deposits.

Remote-controlled robotic equipment can support workers during large scale viral outbreaks, such as COVID-19, and mitigate the impact of future pandemics on the mining industry, by limiting contact between personnel during mining operations.

More systems are now connected digitally, and the proliferation of sensors with the “Internet of Things” has provided a vast amount of data. AI and machine learning have aided a move from response and corrective actions to preventive measures. Operators are now able to make better-informed decisions to safely enhance production efficiency.2

Industrial Revolutions.

How Lithium-ion Batteries Impact the Environment?

Lithium battery innovations continue to set the gold standard for more efficient battery systems; however, the raw material extraction for LIBS often results in detrimental outcomes to the environment.

Soil Contamination

In Argentina’s Salar de Hombre Muerto, residents have placed blame on lithium mining operations for the contamination of streams resulting in livestock and soil contamination. Mined mountains in Chile demonstrate the irreversible impact lithium mining can cause on natural landscapes and ecosystems.7

Water Contamination

More than half of the world’s supply of lithium is in South America, covering parts of Bolivia, Chile and Argentina. In Chile’s Salar de Atacama, mining resulted in the consumption of nearly 65% of the region’s water. Displacement of water access has impacted farmers, forcing them to find alternative sources.7

Additionally, processing chemicals, such as hydrochloric acid, can leak into the water supply. Toxic compounds leeching into the water supply have been found in Nevada, 150 miles downstream of lithium processing operations, hurting the local fish and their habitats.3

Carbon Footprint

LIBs raw materials are primarily responsible for the energy and carbon footprint in the production of lithium batteries. Approximately 40% of the total climate impact of LIBs is due to the mining, conversion and refining of the active materials of the cell.4

The cell production is the second-most energy-consuming process with 20% total CO2/kWh.4 Several innovative processes are being developed to mitigate the environmental impact of LIBs raw material production.

5 Strategies to Reduce the Environmental Impact of LIBs

- The Zero Carbon Lithium™ Extraction Technique

Created by Vulcan Energy, utilizes geothermal power rather than fossil fuels to power extraction processes. As part of the EU’s climate agenda, Vulcan aims to produce lithium for 1 million batteries per year. Their production is set for the beginning of 2024 and will significantly develop the EU’s ability to produce its own domestic car batteries.

- Subsurface Brine Extraction

Lithium salts such as lithium carbonate or lithium hydroxide monohydrate, are currently produced at a typical purity of 99.5%. However, there is increasing demand for lithium with 99.99% purity.

Higher purity lithium salts ensure battery performance, reducing of impurities such as sodium, that can cause battery failure and overheating. Use of high purity lithium can generate more efficient battery systems, leading to increased battery longevity, reduced waste and better environmental outcomes.

- Determination of Impurities

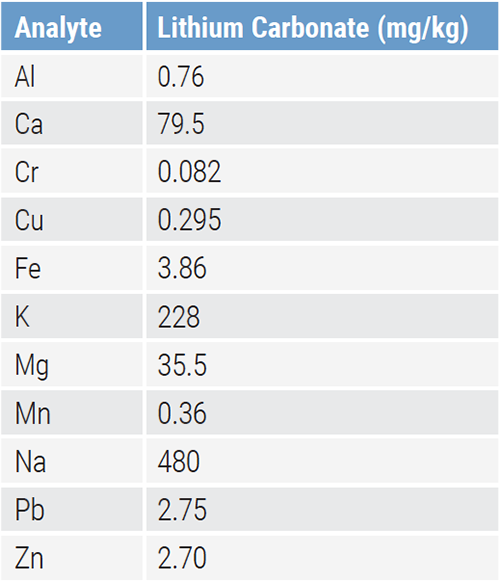

A cornerstone technology for the determination of impurities in high-purity metal raw materials is ICP-OES. PerkinElmer Avio 550 ICP-OES possesses the required sensitivity to perform high purity analyses, making it an excellent option for high-purity lithium extraction.

Additionally, its sample introduction systems are resistant to high salt matrices and highly corrosive samples. Table 1 shows various analytes identified in high-purity lithium carbonate raw materials used in LIB production.

Table 1: Analytes in High Purity Raw Materials Used in Li-Battery Production-Lithium Carbonate.

- Recycling

There will be nearly 11 million tons of previously used LIBs by 2030.6 Recycling LIBs is going to be instrumental in ensuring an adequate supply of raw materials while mitigating damage to the environment.

- Repurposing

Repurposing spent batteries is another strategy to reduce the toxic waste and pollution burden associated with this projected LIB expansion. After an electric vehicle’s battery capacity drops below 70-80%, they lose the ability to power the car.8 However, they retain enough capacity for other functions requiring stationary storage such as household and industrial power applications.

Based upon their efficiencies and reliabilities, it seems LIBs are here to stay. In response to safety and environmental obstacles, the LIB industry has pushed for increased safety in raw material procurement and processing, leading to the utilization of Industry 4.0 safety solutions such as remote operations, robotics, and automation.

To address the environmental impact of LIBs development, industry professionals must continue to innovate with green energy extraction methods. Perhaps, some of the most impactful actions the energy industry can implement is LIBs repurposing and recycling, which has the potential to improve LIBs sustainability dramatically.

Innovators continue to work toward overcoming major environmental and safety obstacles so lithium-ion batteries can continue to play a key role in the alternative energy revolution.

References:

- Industrial Minerals. (n.d.). Retrieved May 13, 2022, from www.indmin.com website: https://www.indmin.com/Article/3298690/Graphite-pollution-fears-spread-to-Heilongjiang-China.html

- Modern Mining Trends and Challenges. (n.d.). July 14, 2021. PerkinElmer. https://f.hubspotusercontent40. net/hubfs/547446/LabManager/Downloads/ PerkinElmer/203724%20WTP%20Mining%20TrendsFINAL%20(002).pdf

- Institute for Energy Research. (2020, November 12). The Environmental Impact of Lithium Batteries. Retrieved from IER website: https://www.instituteforenergyresearch.org/renewable/the-environmental-impact-of-lithium-batteries/

- What is the environmental impact of lithium batteries? (n.d.). Changeit.app. https://changeit.app/blog/2021-03-26- environmental-impact-of-lithium-batteries/

- The Mining and Refining Challenges to Produce High Purity Lithium. Hanton, D. Scott. Lab Manager. July 19, 2021. https://www.labmanager.com/big-picture/lithium-ionbattery-production/the-mining-and-refining-challenges-toproduce-high-purity-lithium-26230

- Low-Temperature Molten-Salt-Assisted Recovery of Valuable Metals from Spent Lithium-Ion Batteries. ACS Sustainable Chem. Eng. 2019, 7, 19, 16144– 16150. August 26, 2019. https://doi.org/10.1021/ acssuschemeng.9b03054

- The Analytical Needs for Recycling Lithium-Ion Batteries. Nowak, Sascha. Lab Manager. July 19, 2021. https:// www.labmanager.com/big-picture/lithium-ion-batteryproduction/the-analytical-needs-for-recycling-lithium-ionbatteries-26231

- Feasibility of utilising second life EV batteries: Applications, lifespan, economics, environmental impact, assessment, and challenges. (2021). Alexandria Engineering Journal, 60(5), 4517–4536. https://doi.org/10.1016/j. aej.2021.03.02