Spectroscopy is the New Sommelier for Modern Vintners

When you consider shifts and changes in an industry, you often need to ask, ‘how did it get to be this way?’ When it comes to the winemaking industry, the answers are as complex and mysterious as a Chateau Lafite Rothschild Bordeaux.

There are several reasons why the industry has changed for vintners (also known as winemakers). One factor is how shopping for wine changed during the COVID-19 lockdown… with the nuances of sniffing “crisp oaky notes” lost when buying online. Plus, the pandemic has impacted the availability of raw materials. This forced winemakers to get creative and adapt their business models and winemaking techniques to adjust to this new frontier.

The broadening of geographic locations has also led to changes in the manufacturing and testing of wine. But what has not changed and perhaps never will is the pivotal role quality control plays in ensuring consistency of flavor, taste, and product safety.1

How can a vintner meet these demands? The answer lies in technology.

Wine producers turn toward science and technology to help them meet legislation requirements, quality standards, import/export guidelines, and individual brand standards to create the flavor, aroma, color, and clarity that make each wine unique. Fourier transform infrared (FT-IR) spectroscopy instrumentation is now being used to monitor the winemaking process by measuring critical parameters throughout vinification, thus enabling more comprehensive process control. FT-IR can reduce the complexity of testing procedures and cut back on the upfront investment required to purchase instrumentation.2

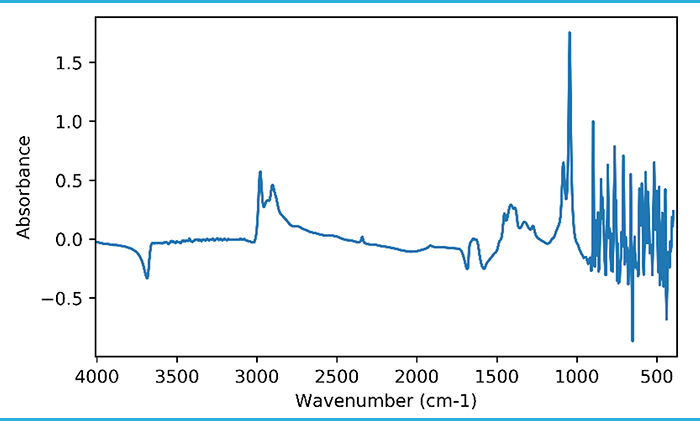

Figure 1. The spectrum of a wine sample generated with the PerkinElmer LQA 300 FT-IR instrument.

FT-IR instrumentation uses spectroscopic imaging to map samples by creating an infrared spectrum of the absorption or emission of components in the model across many wavelengths. Spectral images, such as those shown in Figure 1, are then compared to a library of known components to identify and quantify compounds in the sample. Modern FT-IR instruments can produce results in less than a minute and are small enough to transport in the trunk of a small sedan – to serve as an essential tool in the winemaking process.3

The Art and Science of Winemaking

The science of wine and winemaking is known as enology, and vintners take this process very seriously. Winemaking is an old process that has been around since, believe it or not, the stone age. Farmers who lived 8,000 years ago are the world’s earliest known vintners – producing wine on a large scale as early as 6,000 B.C., a time when prehistoric humans still relied on stone and bone tools.4

The process has changed in many ways over the years. There are now six clearly defined steps in the winemaking process.

The 6 Steps of Winemaking

- Harvesting. This step considers the potential impacts of unfavorable climate changes, testing grapes to determine harvest dates.

- Crushing. After choosing the grapes, vintners destem and crush them using a pneumatic press. These presses also contain a large plastic balloon that slowly inflates to break up the grape skins gently.

- Pressing. Inside the wine barrel is a large Archimedes screw, which moves a platform down, crushing and pressing the grapes.

- Fermenting. Fermentation is a chemical process that involves the conversion of one molecule of glucose into two molecules, each of ethanol (or ethyl alcohol) and carbon dioxide: C6H12O6 → 2C2H5OH + 2CO2.

- Clarifying. Insoluble matter suspended in the wine is removed before bottling, so the wine is clear, not cloudy.

- Aging And Bottling. Almost every red wine and some whites are aged in oak to add flavor and tannins. Aging also allows winemakers to make sure all chemical reactions have taken place. This process happens in 3-9 months at a minimum; then, the wine can be bottled.

Testing grapes throughout the growing process and during harvest using an FT-IR can help determine product soundness, optimal grape maturity, and fair pricing. From harvesting to fermentation, aging, and bottling, staying ahead of the curve with equipment that enables robust quality and process control will serve winemakers now – and far into the future.

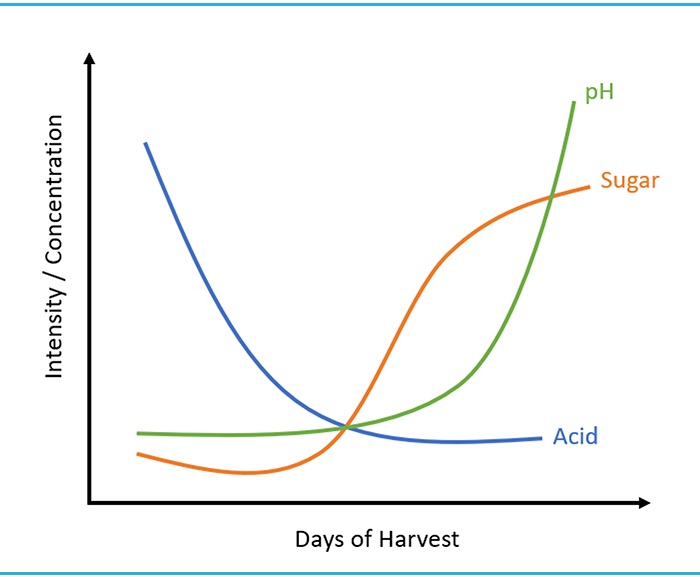

Figure 2. Conceptual model of acid, pH, and sugar content in grapes during the harvest season.

Credit: Food Quality & Safety3

Data used from analyzing samples helps winemakers establish a manufacturing process that is reliable, efficient, scalable, affordable, and provides a good ROI and good profitability in this highly competitive category.

Another critical factor is how long a grape is allowed to stay on the vine. Grapes are harvested fully ripe and do not gain sweetness after they are picked. As grapes mature on the vine, acidity decreases while their sugar content increases. Sugar content is measured to ensure there is enough sugar in the grape to be converted into alcohol during vinification.

Wine experts and sommeliers refer to a lengthy time on the vine as “the noble rot.” This time can add to the residual sugars, alcohol content, and the complexity of flavors that occur during fermentation: this is more commonly seen with red grapes.

Much like yeast consumes sugars during breadmaking, yeast consumes sugars during winemaking. The yeast metabolizes nitrogen in grape juice and exudes a liquid that releases carbon dioxide and ethyl alcohol. Without sugar as a substrate used to obtain nourishment, yeast could not produce the carbon dioxide gas and ethanol needed to make wine.

The pH, sugar, and acidity levels should also be tested in juice as it undergoes fermentation to monitor the yeast’s progress. This monitoring provides clues into how much longer the juice needs to ferment.

The alcohol content of red wine can be as high as 15% because the grapes used have more sugar, so fermentation leads to a higher concentration of alcohol.

The alcohol content in white wine can vary from 5% to 14% due to the fact white grapes tend to be less ripe when used in fermentation, so the sugar converts to ethanol at a lower rate.

Testing at the Blending and Bottling Stage

Winemakers NEED TO KNOW if their finished product meets Q.C. standards. Measuring the amount of residual sugar left in the wine is imperative – as too much sugar could lead to further, unwanted fermentation. The acidity and pH should be tested, and there should be no malic acid present – malic acid can cause the wine to spoil during aging. Finally, measuring ethyl alcohol content is essential at the bottling phase to ensure accurate labeling.

How FT-IR Can Help Meet Consumer Demands

Using onsite FT-IR testing allows winemakers to monitor pH, total acidity, and individual acids in one analysis without slowing down the process. Therefore an honest taste profile and description can be obtained by monitoring pH. Today’s consumers often demand honesty, clarity, and transparency about products. FT-IR testing enables winemakers to ensure the acidity, body, sweetness, flavor, tannin levels, and other qualities that define a type of wine – and a brand. Safeguarding reproducibility and the consistency of a process is paramount in wine production, now more than ever.

There are 83 million Millennials in the U.S. today – and their likes and dislikes differ from those of previous generations. They desire transparency and clarity about what they are buying, and they take the time to study brand culture and the purity of ingredients. To satisfy this large target group, experts suggest that winemakers assiduously list their ingredients and offer nutritional data, like calories per serving, and that they be clear about their social values, efforts to address environmental concerns, and green business practices5.

Wine is among the oldest beverages known to humankind – but the quality of wine and the understanding of winemaking as an art and science has changed throughout the ages. This libation represents a complex matrix of molecules and factors such as grape variety, stage of maturity, and winemaking techniques that make a powerful impact on the quality of the finished product. FT-IR instrumentation can help winemakers avoid costly quality issues, improve profit margins, and ultimately increase revenue.

Ready to take the next step? Find out more about the LQA 300 FT-IR Wine Analyzer.

NOTES:

- Jancis Robinson (ed): “The Oxford Companion to Wine” Third Edition, pp. 267–69. Oxford University Press 2006 ISBN 0198609906.

- https://www.svb.com/globalassets/trendsandinsights/reports/wine/sotwi-2021/svb-state-of-the-wine-industry-report-2021.pdf

- https://www.foodqualityandsafety.com/article/ft-ir-spectroscopy-wine-testing-benefits/

- https://www.nationalgeographic.com/history/article/oldest-winemaking-grapes-georgia-archaeology#:~:text=The%20people%20living%20at%20Gadachrili,on%20stone%20and%20bone%20tools.

- https://www.nytimes.com/2022/02/07/dining/drinks/wine-millennials.html#:~:text=Millennials%2C%20the%20generation%20that%20began,them%20to%20become%20regular%20consumers.

- https://www.sciencedirect.com/science/article/pii/S0144861722002697