Analyzing Advanced Materials in the Automotive Industry

The Materials Advancing Car Design & How to Test Them

Advanced materials are enabling key improvements to automotive vehicles that benefit both manufacturers and end-users, but what are the options for reliable testing?

Development and integration of advanced materials are enhancing vehicle design and manufacturing capabilities. These materials are pivotal in boosting vehicle performance, safety, fuel efficiency, and sustainability.

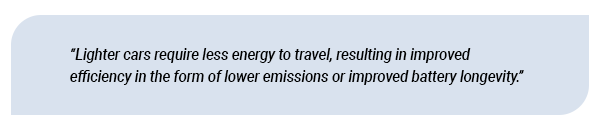

Uses of advanced materials in automotives range from tire rubber to polymer cables, elastomers, and other silicone rubber engine components, as well as for car interiors and seating. However, all these materials must undergo robust testing processes to ensure that they can withstand the demands endured over the long term.

Lightweight Materials Improve Fuel Efficiency

Lightweight alternatives such as carbon fiber-reinforced composites and advanced polymers are increasingly replacing traditional metals such as steel and aluminum. Not only do these materials offer improved strength-to-weight ratio, but lighter cars require less energy to travel, resulting in improved fuel efficiency and lower emissions, and improved battery longevity where battery-powered vehicles are concerned.

While steel remains an essential material in the industry, recent innovations have led to the development of high-strength steel (HSS) alloys. These alloys are solid and lightweight, making them ideal for reinforcing crucial parts of a vehicle’s structure while reducing overall weight. Similarly, aluminum has been a crucial material for decades. Yet advanced aluminum alloy technology has made it even more appealing for automotive manufacturers by offering improved strength, corrosion resistance, and durability. Depending on your detection requirement inorganic analysis using AA, ICP-OES or ICP-MS will be used to quantify metals and alloys.

Testing Techniques & Technologies

The application of the advanced material in the car will dictate what testing requirements must be in place. Some materials will need to be tested for performance under heat and pressure, others for resistance to wear and friction. This also extends to off-gassing safety assessments, responsible for the ‘new car smell’, for plastics in interiors.

PerkinElmer work with manufacturers investigating advanced materials by providing analytical instrumentation, expertise, and support services to advance research. Our solutions can perform a full spectrum of analysis on advanced materials, monitoring any changes in rheological properties within dynamic conditions, strictly controlling temperature, time, frequency, stress, atmosphere, or a combination of these parameters.

If handling high volumes of samples, you can reduce the time between analysis cycles with the fast cooling available from the PyrisTM 9 line of thermal instrumentation. Super-fast cooling rates enable customers to run more batches and make significant efficiency savings through continued use.

Mechanical Analysis in Rubbers

Polybutadiene rubbers are used for applications where the ability to deform and return to the original shape is of vital importance, such as for car tires, wiper blades, and gaskets. Dynamic mechanical analysis (DMA) is highly effective in characterizing the material and assessing the performance of the final product to ensure optimal compound properties, and compliance with international abrasion standards.

Stimuli Responsive Materials

A new frontier of materials employed in automotive is represented by the stimuli responsive materials, which are materials that adapt their properties and characteristics depending on changes in external conditions. Some of these materials include thermos-responsive materials and electroactive polymers. Typically these materials are based on polyacrylamide in the first case and PVDF derived materials in the second. TGA and DSC represent two important techniques to characterize and evaluate the quality of these materials. In particular, the thermal stability, degree of crystallinity and phase-change behavior of these polymers is important to guarantee the right response of the materials to the external solicitation.

Nanomaterials Driving Change

Thermogravimetric analyzers (TGA), Fourier-transform infrared spectroscopy (FTIR) instruments, and ultraviolet/visible/near-infrared spectroscopy (UV/VIS/NIR) equipment perform other essential analyses for polymer parts of all kinds like cables and molded-plastics used in the automotive industry.

Coatings and paints are other materials that have seen great advancement in the last few years by the addition of inorganic or carbon material that can be characterized by FT-IR and UV-Vis Techniques. In fact, the implementation of additives in the coating and paint mixtures impart new properties that resolve challenges like the softening, delamination, and cracking that polymeric films normally face. Carbon nanomaterials like Carbon nanotubes (CNTs) and Nanoparticles (NPs) are frequently employed for this purpose. Various NPs, including ZnO, FeO, CeO, TiO2, and silica, for example are introduced into traditional coatings to improve their resistance to sunlight. NPs having a wide surface area for absorbing the damaging component of sunlight (ultraviolet part) protect coatings against weathering deterioration.

Testing the final composites and determining the effect of additives is essential to understand material improvements. In this context, FT-IR and UV-Vis can furnish important information regarding the polymer composition and the effect of the additive on spectroscopy properties of the final materials.

Hyphenated Solutions & 3D Printing

Such solutions can also be hyphenated, or joined together, to perform the most in-depth analysis available for advanced materials, as may be required. For example; DSC/TGA and FT-IR instruments are frequently used to characterize advanced coatings and paints, including emerging smart coatings and epoxy resin, and can be coupled to a gas chromatography mass spectrometer (GC/MS) to determine possible degradation products from evolved gas produced.

Furthermore, with 3D printing using specialized additive materials surging in popularity in the automotive industry, parts are increasingly customized and prototypes can be created quickly. With such experimental manufacturing techniques, these additive materials must be rigorously tested, including monitoring the chemical nature of evolved gases during 3D printing. Hyphenation of TGA with FTIR, MS, and GC-MS instruments allows manufacturers to better understand evolved gases. The PyrisTM 9 thermal range at PerkinElmer provides complete control over the sample environment and thanks to its super-fast cooldown rate, delivers high throughput and reliability, with the option to work autonomously if required.