6 Ways Packaging Can Fail (And How Testing Can Prevent It)

Plastics play an important role in food packaging, with safety at the forefront. Plastic packaging serves the purpose of helping people gain access to items they need while preventing tampering and ensuring product consistency. Packaging can be defined in three levels: primary packaging is used to encase food or pharmaceutical products, secondary packaging is usually exterior packaging used to protect or label these items, and tertiary packaging is used for storage and distribution.

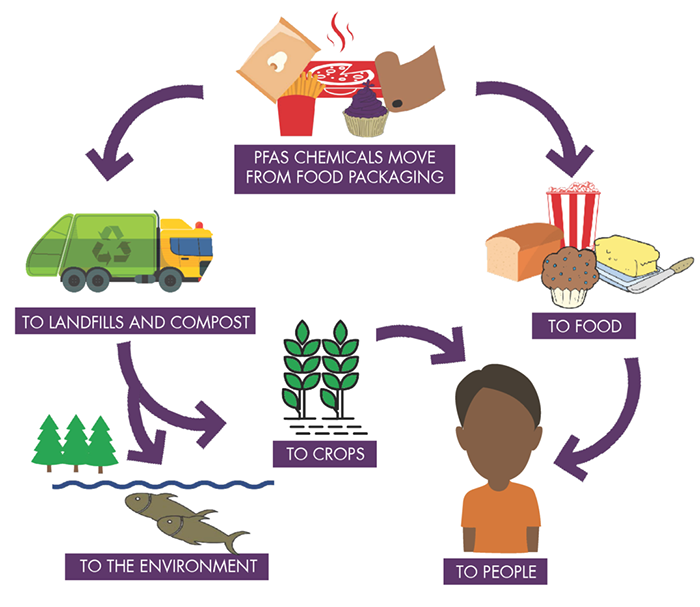

With more than 40% of manufactured polymers being used in food or pharma packaging, testing polymeric materials for safety and durability has become a high priority. The diagram below demonstrates the relationship humans have created with plastics and plastic waste.

Image Credit: ToxicFreeFuture.org

The purpose of packaging analysis is two-fold: 1. To prevent external contamination from entering the product to be ingested, and 2. To avoid having the packaging become a source of contamination to people, animals, and the environment.

Packaging has become well-regulated and governmentally legislated with basic requirements that help protect consumers by ensuring the integrity and safety of ingested items. As indicated in the table found here, when packaging fails, serious and far-reaching problems can follow suit.

| How Packaging Can Fail | Consequences | What to Test / Detect / Measure | Instrumentation To Use | Example Of Packaging | |

|---|---|---|---|---|---|

| 1 | PAHs leaching out of plastic | Human health protection – asthma, endocrine disruption, reproductive abnormalities, cancers | Phthalates (PAHs levels) | GC/MS LC/MS/MS | Plastic milk cartons |

| 2 | Residual solvents leaching out from label inks and adhesives | Human health protection, meet EN 13628-2:20041 | Ethanol, isopropanol, and other key residual solvents | GC/HS and Flame Ionization Detector (FID) | Printed labels on food packets |

| 3 | Recycled material having foul odors, and contaminants | Eliminate bad odors and enable the recycling separation process | Polymer compound identification & VOC detection e.g, benzene, acetaldehyde, and limonene | FTIR GC/HS and Flame Ionization Detector (FID) | Soft drink bottles |

| 4 | Chemicals leaching into the environment | Prevent molecules entering the soil, water, and food chain | Fire retardants PFAS/PFOS chemicals | LC/MS/MS | Microwavable meals and fast food |

| 5 | Failure of physical package | Human health protection of contents and prevention of oxidation | Layer structural analysis VOC detection (see 1 & 2) | Optical microscope FTIR spectra GC | Polylaminate films |

| 6 | Decay into Microplastic pollution | Prevent entry into the environment | Polymer compound identification | FTIR Microscope such as a Spotlight™ 200i | All packaging waste |

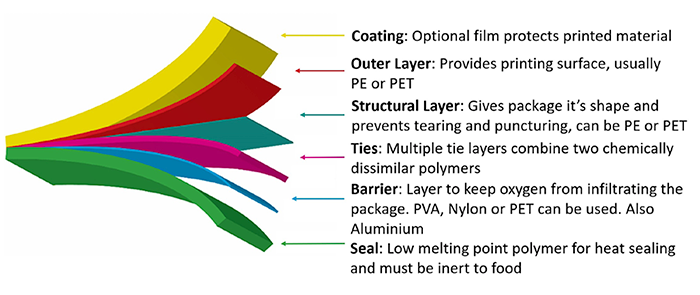

Most food packaging is multilayered and made of laminates, much like the example below. Barrier layers within packaging can ensure food safety, add shelf-life, and can create an oxygen, aroma, and flavor barrier. Layered food packaging protects food, improves manufacturing operations, reduces damage and waste, enables better retail and food service storage, and more. However, plastic packaging adds just as many layers of concern.

Structural layers of laminated packaging typically found in food packaging

In recent decades it has been discovered that chemical compounds and microplastics can leach out of the packaging. As a result, scientists and government departments are collaborating to prevent leaching and other dangerous issues from occurring through the analysis of chemical structure, temperature, storage time, humidity, physical characteristics and other factors.

Food regulation continues to improve and evolve. Researchers and regulators are actively working together to identify leachable compounds and determine acceptable levels for the safety of human health, animal health, and the environment. New threats are likely to emerge. For example, PFAS started as an environmental issue and has rapidly evolved into a food safety issue.

Learning how to better test, detect, and measure plastic packaging will surely continue to evolve, creating real-world solutions to this ongoing concern.