Producing Quality Paint is Jotun’s Job – Analyzing It Is Ours

For almost a century, Jotun products have protected all types of property – iconic buildings and private homes, commercial vessels, and onshore and offshore petrochemical plants and refineries. Headquartered in Sandefjord, Norway, and doing business in more than 100 countries around the world, they’re one of the world’s leading manufacturers of paints and coatings, combining top quality with continuous innovation and creativity.

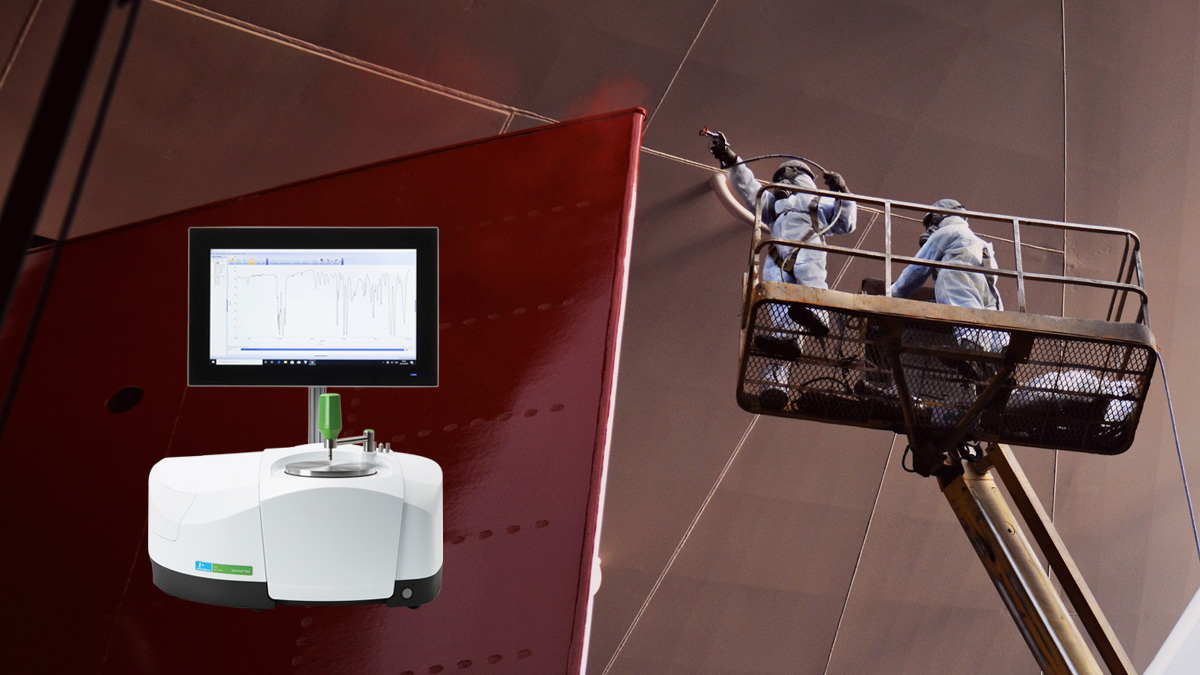

And they’ve got quality control and testing covered, too, using several analytical testing techniques, including FTIR analysis for chemical characterization of raw materials at R&D labs and production sites. As a matter of fact, Jotun has had a long and fruitful collaboration with PerkinElmer when it comes to FTIR, providing systems that combine modularity, flexibility, and safety with ease of use and robustness for unprecedented efficiency in industrial laboratories – all in one system.

“FTIR is a technique that is easily utilized – it can deliver pass/fail results, making it optimal for comparative models in quality control,” says Dr. Åsa Marand, R&D manager for Corporate Services at Jotun. “When it comes to the research lab, we utilize a lot of FTIR, but these analyses aren’t simple, and our scientific expertise is important to achieve proper interpretation of the IR spectra.”

Heidi Lindstrom, chief chemist at Jotun, agrees: “Monitoring samples is a vital component of what we do – we need to understand how the process of wet paint through to the dry film will act and what may be happening. Many chemical composition studies are not as easy as pass/fail, because many paints and coatings we work on are not that simple. For example, coatings manufactured for ships have several systems within their coatings, like primer, mid-coat, and topcoat. These are studied to detect and measure any interaction of one system to another, whether intentional or nonintentional.”

All these innovations contain complicated chemical processes that need investigation and, in many cases, require conformance to global ASTM standards.

Want to find out more about coatings and paints analysis? Visit here to learn more