From Mines to Markets: A to Z in 17 REEs

One of the most critical issues facing mining operators today is also the rarest: we’re talking, of course, about rare earth elements – the global trends affecting mines and the downstream industries that rely on them, and the key analytical techniques underpinning essential work in elemental identification, characterization, and quantification.

For the last 20 years, rare earth elements (REEs) have become essential components of rapidly expanding industries such as electric vehicles, smartphones, fiber optics, ceramics, and various industrial applications. Their electrochemical, magnetic, and optical properties position REEs to be key elements of interest in the mining industry for the foreseeable future.1

What Are Rare Earth Elements?

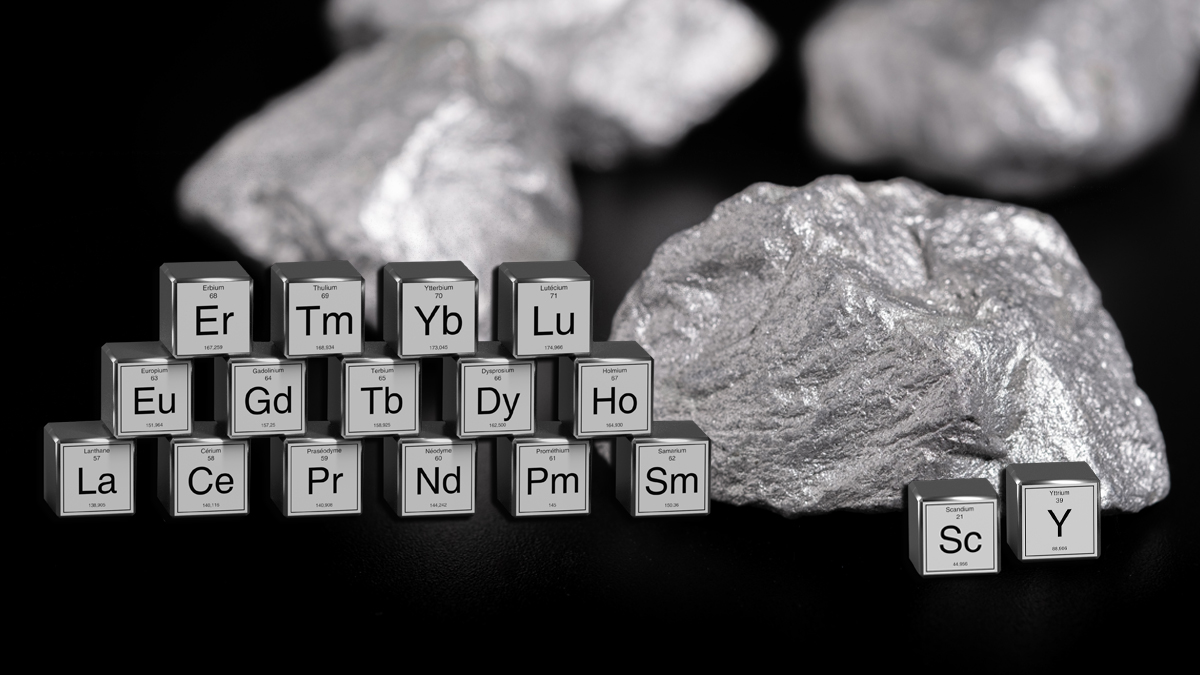

There are 17 REEs, with 15 of the 17 belonging to the lanthanide family. Scandium and yttrium aren’t lanthanides, but they’re typically found in the same mineral deposits and have similar chemical properties.1 Table 1 outlines all the REEs being mined globally.

Table 1: All 17 REEs

| Sc | Scandium | Gd | Gadolinium |

| Y | Yttrium | Tb | Terbium |

| La | Lanthanum | Dy | Dysprosium |

| Ce | Cerium | Ho | Holmium |

| Pr | Praseodymium | Er | Erbium |

| Nd | Neodymium | Tm | Thulium |

| Pm | Promethium | Yb | Ytterbium |

| Sm | Samarium | Lu | Lutetium |

| Eu | Europium | ||

REE Applications

Rare earth elements have electrochemical, magnetic, and optical properties that make them excellent catalysts for industrial applications, magnet manufacturing, glass-polishing powders and additives, battery components, ceramics and pigments, and phosphors.1 Their unique properties enhance alloy and magnet performance, making them perfect for electronic equipment such as computers and smartphones.1 As a result of the green energy revolution, REEs are becoming key components in electric vehicles and generators for green energy applications such as wind turbines.1 Figure 1 outlines key REE applications.

Figure 1: Key Applications of REEs

Global Demand for REEs

As of 2020, China leads the world with nearly 38% of the total REE reserves and more than 57% of the global mining production.1 By comparison, the United States holds only 1.3% of the total REE reserves and approximately 15.6% of the global mining production.1 China’s significant position in the REE market is a direct result of intensive research initiatives and strong industrial policy.1 Even though China’s global production of REEs has steadily decreased from 2010, when they controlled 92% of the global REE production, they still maintain 85% of the global refined REEs due to their supply-chain dominance.1

As the world’s demand for REEs rapidly increases due to electronic innovations and sustainable energy initiatives, REE mining production will need to grow at a commensurate rate. Untapped reserves in China, Vietnam, India, Brazil, and Russia will represent the hotspots for REE mining production.1

REE Mining Initiatives in the United States

In the past, several REE mining opportunities have provided the United States a chance to gain ground in their mining production capacity but have been hindered by a combination of minimal political support and limitations of small-scale production.2 Fortunately, the Biden Administration is investing nearly $30 million to support research and secure the United States supply chain for domestic REEs and minerals supporting battery components.2 The Biden Administration has also signed an executive order to determine gaps in the domestic supply chains for REEs and other key resources.3

REE Digitalization, Sustainability, and Recycling

The future landscape of REE mining suggests that digitalization technologies will help optimize productivity while ensuring the sustainability of operations through the minimization of resources and labor.4 The digitalization of REE mining operations will no doubt assist operational efficiency at every step of the mining workflow but will have a significant impact on small-scale operations where resources and labor bottle-neck productivity.4

Roughly 11 million tons of previously used lithium-ion batteries (LIBs) will exist by 2030.5 Recycling LIBs and other used technological equipment is going to be instrumental in ensuring an adequate supply of REEs and other raw materials while mitigating damage to the environment.5 The recycling process of battery components begins with deactivating and shredding the old battery module, which is discharged and dismantled.5 The dismantling of the module occurs under inert atmospheric conditions to avoid thermal runaway.5 Volatile electrolyte residues are removed, and hydrometallurgical procedures are carried out using pH-dependent precipitation of salts to recover raw materials. 5 Characterization of LIB materials using elemental analysis and cell chemistry is paramount to ensure effective recycling efficiencies.6

Battery recycling will rely on a collection of physical processes and analytical methods to provide the information necessary to begin the initial assessment of the recycling scrap. Analytical testing equipment will play a crucial role in both the characterization of the resynthesized recycled ASSBs and the reduction in the environmental and social impact of battery development.7 Figure 2 shows the key analytical testing technologies needed in the recycling of battery components for REE sustainability.

Figure 2: Key Analytical Testing Technologies for Battery Recycling

Analytical Testing for REE Mining

There will be an increased need for analytical solutions that can accurately characterize and quantify REE content. Technologies such as inductively coupled plasma mass spectrometry (ICP-MS) and inductively coupled plasma optical emission spectroscopy (ICP-OES) are key solutions in this field. These technologies have capabilities that enable mining facilities the ability to rapidly analyze a wide variety of REEs and sample types, while effectively managing matrix interferences.

References

- LePan, Nicholas. “Rare Earth Elements: Where in the World Are They?” Elements by Visual Capitalist, 22 Nov. 2021, elements.visualcapitalist.com/rare-earth-elements-where-in-the-world-are-they/.

- Cohen, Ariel. “The Future Battlefields: Rare Earth Elements.” Forbes, forbes.com/sites/arielcohen/2023/01/26/the-future-battlefields-rare-earth-elements/?sh=572050951c63. Accessed 26 Apr. 2023

- Franck, Lauren Feiner,Thomas. “White House Set to Host Google, Intel CEOs to Discuss Computer Chip Supply Chain.” CNBC, cnbc.com/2021/04/09/white-house-set-to-host-google-intel-ceos-to-discuss-computer-chip-supply-chain.html . Accessed 26 Apr. 2023

- “Digitalization Trends and Sustainability in the Global Mining Industry.” www.youtube.com, youtube.com/watch?app=desktop&v=dbCNjEJQQ5w. Accessed 26 Apr. 2023

- Low-Temperature Molten-Salt-Assisted Recovery of Valuable Metals from Spent Lithium-Ion Batteries. ACS Sustainable Chem. Eng. 2019, 7, 19, 16144– 16150. August 26, 2019. https://doi.org/10.1021/ acssuschemeng.9b03054

- The Analytical Needs for Recycling Lithium-Ion Batteries. Nowak, Sascha. Lab Manager. July 19, 2021. Analytical Testing Drives Production of Lithium-Ion Batteries | Big Picture | Lab Manager

- The Analytical Needs for Recycling Lithium-Ion Batteries. Nowak, Sascha. Lab Manager. July 19, 2021. https://www.labmanager.com/big-picture/lithium-ionbatteryproduction/the-analytical-needs-for-recycling-lithiumionbatteries-26231