3 Ways Asset Management is Driving Lab Efficiency and Success

Robust asset management is the bedrock of any lab. Ensuring equipment is well maintained and kept will keep efficiency high. To get ahead of their increasingly complex day-to-day activities, higher throughput demands, and ever-growing cost pressures, labs need to be as efficient and optimized as possible.

- Save Money by Increasing Productivity

It’s well-known truth in any lab: time equals money. Therefore, the less time scientists spend waiting for equipment and the more time they spend on relevant tasks, the more cost-effective a lab will be. However, with the support of a multivendor asset management service, like PerkinElmer OneSource, these jobs can be outsourced, allowing scientists to focus on discovery and research.

From the very first stage of an equipment’s lifecycle, during onboarding, lab teams spend valuable time on tasks such as scheduling logistics, coordinating tracking, and software installation. Furthermore, overlooking minor details can lead to delayed installation, unforeseen costs, and unexpected downtime, leading to even more time lost on non-research tasks.

This infographic details how a comprehensive onboarding service can save labs time and money.

- Reap the Rewards of Good Lab Maintenance

Even once the equipment is up and running, a lab’s challenges don’t stop there. Regular equipment maintenance is vital whether to stay within budgets or ensure that experiments run effectively and without a hitch.

However, the benefits of routine equipment maintenance don’t end there. Equipment is often one of the highest cost outlays for a lab, so avoiding unnecessary re-purchases is a big bonus.

It’s important to note that maintenance must be tailored to a lab’s individual needs and challenges. For example, in industries such as Pharma and food, regulations and standards for labs are constantly changing due to global trends and safety challenges. Here, labs must ensure that routine maintenance targets any changes in operating procedure and protocol to ensure compliance.

Additionally, while almost all instrumentation needs servicing, there is a large variety of workflows, with some containing complex instrumentation such as NMR spectrometers and others containing much simpler equipment, such as balances or pH meters. Dedicated and tailored customer service ensures the best ROI.

Use this graphical chart to help choose the right maintenance model.

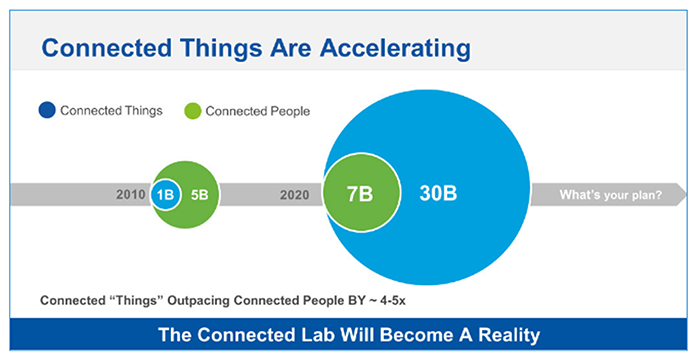

- Leverage the “Internet of Things” (IoT)

This term has become a household word to describe the intersection of devices and the massive exchange of data across the internet. From carbon monoxide devices to traffic lights, the IoT is commonplace in the modern world—and should be used to create efficiencies in today’s lab.

Just as every lab is unique, so are its workflows and processes. For example, two pharmaceutical QA/QC labs are likely to have very distinct operational workflows. An API lab, for example, would typically test for residual solvents, whereas a more conventional drug might not, leading to different instrumentation and processes. This is why leveraging IoT is so important. The connectivity captures lab-wide contextual data and reduces human error by automating many essential tasks, including monitoring, scheduling, and protocol intervention. Furthermore, through intuitive visualization and data sharing software, the IoT can help get more in-depth, real-time updates about operational workflows.

When working across multiple sites, labs can even be used to benchmark one another to ensure performance is maintained.

By setting SMART metrics, KPIs and goalposts, labs can also continually monitor workflow effectiveness, seeking out bottlenecks as they appear to accelerate efficiency. This automatic data capturing can extend to lab conditions as well. Environmental monitoring, for example, can help improve research reproducibility and instrument performance. Conditions such as temperature, humidity, air pressure, and light levels can all affect instrument performance. While most labs possess some environmental control, they often cannot detect granular changes generated in microclimates. However, with IoT, a tailor-made monitoring system can be made for a specific lab, helping ensure reproducibility and validating conditions for installation.

Asset management is not a single-step process. From the moment a lab decides to purchase new instrumentation, ongoing management is required to get the most out of it. Yet, ensuring the best ROI means can mean spending valuable time on basic maintenance and installation. But there is a more efficient and accurate way. By outsourcing these jobs and getting support from an expert team, a lab can focus on productive scientific discovery and research.

Learn more about OneSource Asset Management now.