How Sunblock Manufacturers Can Prevent Getting Burned

The Ancient Egyptians used rice, jasmine, and lupine extracts to protect their skin from the sun, but the earliest form of commercial sunscreen wasn’t created until 1938 by Swiss chemist Franz Greiter. In 1944 Benjamin Green introduced a mixture of cocoa butter and red veterinary petroleum to protect his skin. Greiter branded his formula Piz Buin® while Green marketed his as Coppertone®. Greiter is also credited with coming up with (SPF) Sun Protection Factor. This rating is still widely used today.1

FDA has regulated sunscreens since the 1970s, but they have recently garnered much attention. Active ingredients like oxybenzone and octocrylene, commonly used in sunblocks, have come under scrutiny because of their tendency to be absorbed by the skin and the possibility of ingestion or inhalation when applied to the face.

Other active ingredients are known to break down when exposed to sunlight, protecting the skin from harsh rays, but resulting in formation of compounds that can cause allergic reactions and chronic health effects. Scientists have also discovered that some of the chemicals found in sunscreen can threaten the health of coral reefs and sea life.2 These concerns have initiated a shift towards the use of mineral ingredients, such as zinc oxide or titanium dioxide, as active sunblocking ingredients.

The Block Thickens

When considering the best course of action to take, many people consider using sunscreen made without chemicals that can harm marine life, seek shade during the hours of 10:00 AM – 2:00 PM, and use Ultraviolet Protection Factor (UPF) fabric sunwear. Ultimately, consumers only have so much control over the quality of their sun protection and must rely upon manufacturers and products to protect them.

Ultraviolet/Visible (UV-Vis) spectrophotometers, like the PerkinElmer® Lambda 1050+, are routinely used to check formulations and ensure they meet the specified SPF rating. However, in both quality and research and development functions, it is often helpful to gain additional information such as how much of the mineral ingredient must be added to achieve the desired SPF rating.

3 Questions Manufacturers Should Consider

- If we prepare a batch of the product, will the mineral be uniformly distributed through the material?

- Might we see some stratification of material which alters the achieved SPF rating across the batch, or even across each package of finished product?

- How will the purity of each batch impact the efficacy and consumer experience?

While chromatographic techniques would have routinely been used to answer these questions for formulations using organic (i.e. hydrocarbon-based, such as avobenzone or octocrylene) active ingredients, the nonvolatile and insoluble nature of mineral pigments makes these assessments more difficult by preventing the quantitation of these materials.

The Answers Are in The Ash

Thermogravimetric analysis of the formulation helps surmount the challenges posed by the heterogenous nature of the product and the properties of the mineral ingredients. Thermogravimetric analyzers (TGA) will heat a small portion of material in a furnace, purged with gas or gases chosen by the user, while a sensitive balance is used to measure and record the mass of the material.

When a sample is heated in the presence of oxygen, organic components will combust, leaving behind mineral species, or “ash”. In the case of mineral-based sunblock products, the “ash” is the active ingredient. The number of “steps” or weight loss events, which occur during combustion of the material, can also provide some insight into the quality or complexity of the formulation.

Comparison of Two Sunblock Formulations

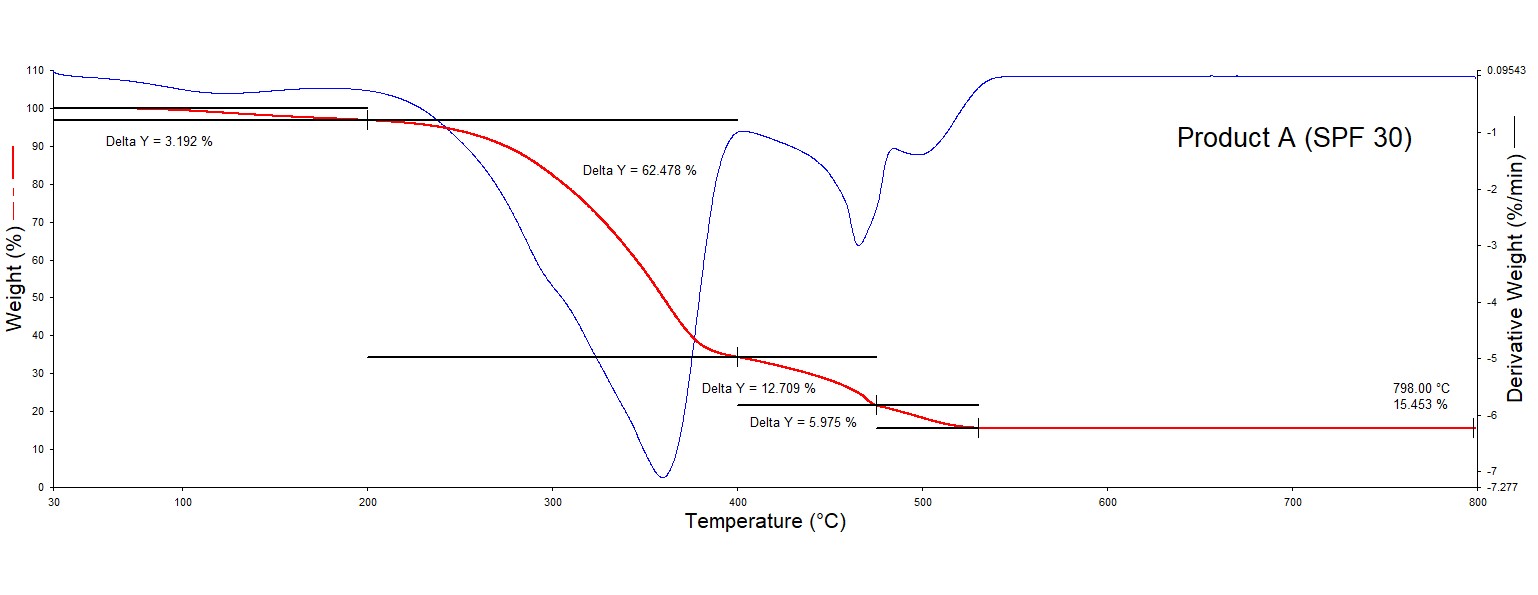

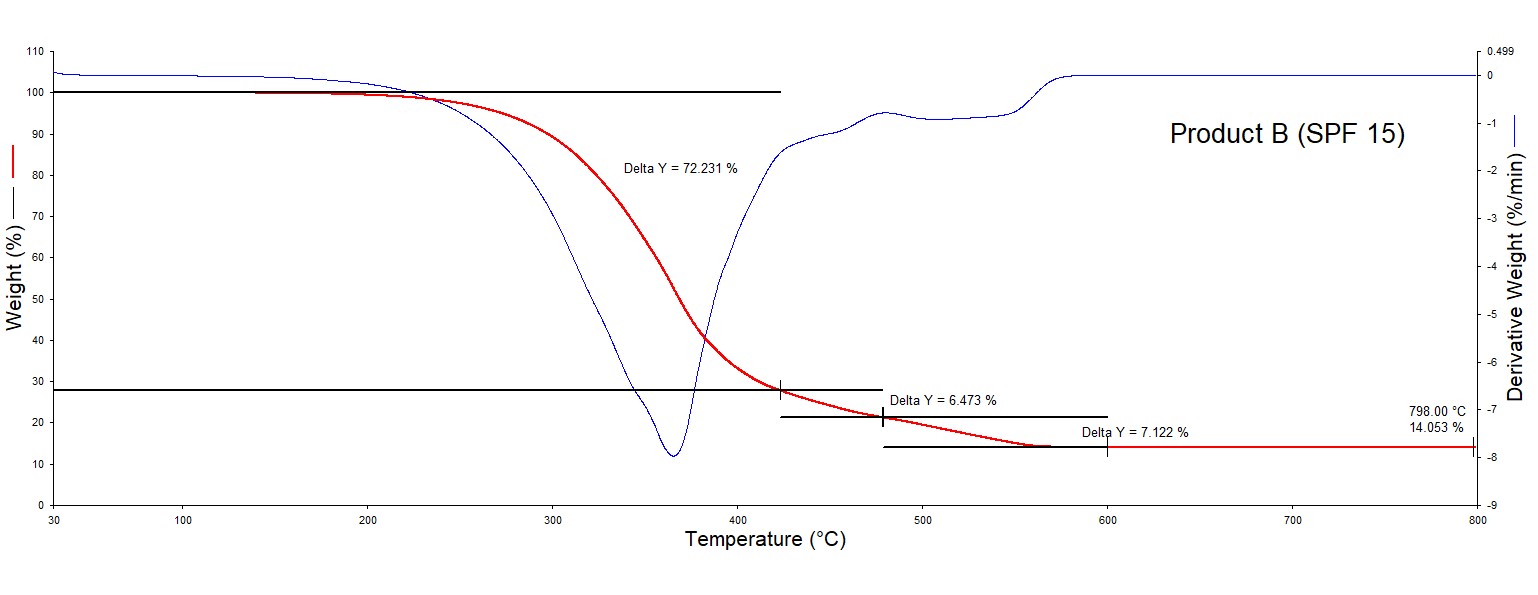

Two sunblock formulations with different SPF ratings were tested with the PerkinElmer® TGA 8000™ thermogravimetric analyzer, producing the thermograms shown below, shown as red curves. Product A, which has an SPF rating of 30, exhibits four weight loss events, while Product B, which has an SPF rating of 15 underwent three weight loss events. The authenticity of these steps is further confirmed through calculation of the first derivative of the thermogram (shown as a thin black line), which shows a “dip” or minimum towards the center of the weight loss step.

The ash content becomes apparent at the end of the measurement, where the temperature has reached 800 Celsius: Product A contains 15.45 wt % mineral additive, while Product B contains 14.05 wt % mineral additive.

From a qualitative standpoint, the formulations contain similar organic constituents (waxes and other ingredients), but in differing proportions. Product A also contains approximately 3 wt % of water, which is liberated around 100 Celsius.

Thermograph of Product A (which exhibits 4 weight loss events) and Product B (which exhibits 3 weight loss events)

Mix it up: Enhancing Quality and Profitability

The global sunblock market size was $13.03 billion in 2019 & is projected to reach $16.84 billion by 2027, at a CAGR of 3.5% in the forecast period with the costs of a tube of the most popular natural brand on the market costing $18 for 1.7 oz.3 Consumers seek products that are not tacky, nonoily, effortless to apply, non-drying with a pleasant scent and formulates with a mixture of zinc oxide and titanium dioxide3.

Measuring the mineral content in sunblock formulations helps manufacturers examine product consistency from batch-to-batch and within-batch. Product efficacy can therefore be controlled, while also ensuring components are not out-of-spec and affecting profitability. Ash can also be recovered from the TGA measurement for further analysis. As an example, the material can be transferred to the attenuated total reflectance (ATR) crystal on an FTIR such as the PerkinElmer® Spectrum 2 or PerkinElmer® Spectrum 3 to identify the mineral ingredients, which can also prove useful for analysis of competitive products.

Until September 30, PerkinElmer is offering a buy one, get one on thermal and IR instruments. Purchase an eligible thermal analysis instrument and receive a Spectrum Two FT-IR Spectrometer. Use promo code: PAIR 2022. Learn more here!

Footnotes:

- https://www.nytimes.com/2010/06/24/fashion/24skinside.html

- https://oceanservice.noaa.gov/news/sunscreen-corals.html

- https://www.fortunebusinessinsights.com/sun-care-products-market-103821