Sustainability + Technology: Lithium and Rare Earth Element Applications

Lithium ion batteries (LIB) have become ubiquitous in our everyday lives. Today, they are found in mobile phones, laptop computers, electric vehicles… even grid-connected energy systems and the International Space Station.

A rapidly growing sector for LIB use is in electric vehicles (EV), the production and use of which are projected to increase enormously over the next 10 to 15 years. This anticipated increase in EVs presents a challenge for lithium suppliers: meet increasing lithium demand while protecting this finite resource from exhaustion, while also adopting greener mining techniques.

Lithium mining operations will contribute to meeting this challenge by developing more efficient methods for lithium extraction and purification while maintaining the stringent 99.9%, or greater, purity level required by LIB manufacturers.

This ultrahigh lithium purity level is crucial for numerous reasons, such as:

- Minimizing LIB fire hazards

- Improving LIB efficiency

- Maximizing LIB lifespan

Increased LIB production will result in increased generation of spent LIB. Even with their advanced chemistry and engineering, LIB currently have a finite usable lifespan, as do all batteries. Many corporate and government research teams are striving to develop recycling methods that improve the recovery of lithium (and other metals) from LIB.1,2 As with mining operations, effective recycling methods will have to provide the 99.9% lithium purity levels required by LIB manufacturers. Keeping LIB out of landfills will also reduce the potential for harmful leachates to enter groundwater and waterways.

Improving the sustainability of Earth’s lithium resources and reducing LIB wastes make these approaches front-runners in sustainability.

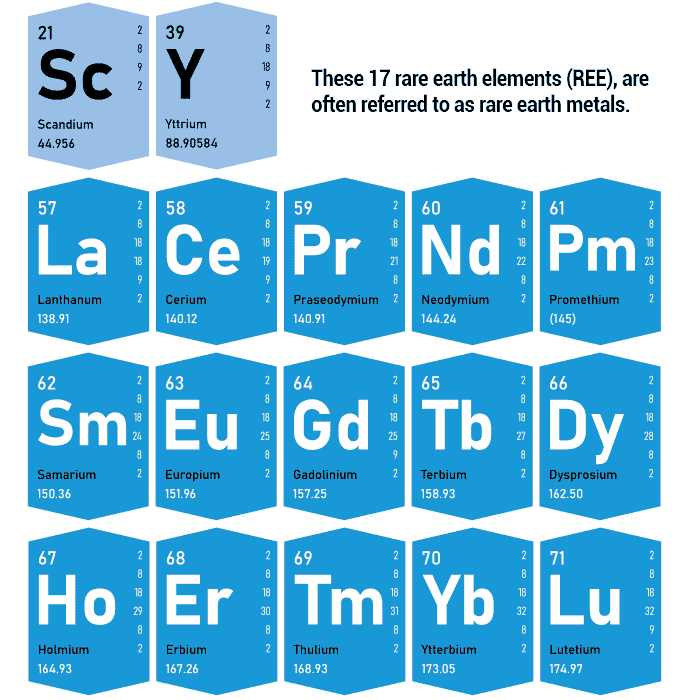

Enhancing Sustainability of Rare Earth Element Applications

The rare earth elements (REE) have unique physical and chemical properties, e.g., optical, magnetic, catalytic, and phosphorescent. Those properties make REE crucially important to a wide range of modern technologies and industries.

For instance, REE are essential components of electronics screens, computer hard drives, LED lighting, batteries in electric and hybrid vehicles, magnets in wind turbines, catalyst-driven industrial processes, and many others. Because of their essential need in so many applications, REE have been nicknamed “the vitamins of modern industry.”

Contrary to the group’s name, REE are relatively abundant in the Earth’s crust. The term “rare” reflects the fact that REE are not present in concentrated deposits. Rather, they are diffuse components of other mineral deposits and, consequently, must be painstakingly extracted from those deposits and thoroughly purified.

Historically, REE extraction has been done using extremely large-scale, liquid-liquid methods that are efficiency-challenged and generate large volumes of toxic waste. Researchers have long been seeking a more sustainable means of obtaining REE from raw ore, and more recently from recyclates and waste streams. Two U.S. university research teams focused on developing solutions to this challenge are Purdue University and West Virginia University.

Researchers at Purdue University have developed a process that removes and purifies REE from raw ore, recycled magnets, and coal ash using a novel chromatography application. The new method uses “a two-zone ligand-assisted displacement chromatography system with a new zone-splitting method that is producing high-purity (>99%) metals with high yields (>99%).” 3

West Virginia University researchers are developing a parallel technology that extracts REE from acid mine drainage (AMD) precipitates generated at coal mines. Their research is focused on an acid leaching solvent extraction (ALSX) method that will be efficient and economically feasible.4

Eliminating toxic waste generation and enabling REE recovery from other waste streams and recyclates makes these new technologies winners in sustainability.

Read the white paper From Mines to Markets: Modern Mining Trends and Challenge for detailed insights.

Sources

- https://cen.acs.org/materials/energy-storage/time-serious-recycling-lithium/97/i28

- https://www.sciencemag.org/news/2021/05/millions-electric-cars-are-coming-what-happens-all-dead-batteries

- Purdue https://scitechdaily.com/new-technologies-to-extract-purify-critical-rare-earth-metals-a-game-changer/

- https://www.netl.doe.gov/node/10422